DOWN DRAFT BASEMENT

What is a Downdraft Basement? A downdraft basement in a spray booth creates powerful, vertical airflow that draws air and contaminants directly downward and away from the vehicle and painter. This results in faster drying times, efficient overspray removal, and a cleaner, healthier workspace. By directing airflow straight down, it prevents contaminants like dust, dirt, and debris from circulating and settling on the painted surface, significantly reducing the risk of imperfections. This ensures a high-quality, professional finish every time. Additionally, downdraft systems promote even air distribution across the entire workspace, leading to consistent drying and paint application, minimizing the need for costly touch-ups or corrections. Their superior contamination control also helps maintain the longevity of your spray equipment and creates a safer working environment for painters. Sizes are fully customizable to fit your specific needs, making them an ideal solution for any shop, whether you’re working on compact vehicles or larger, more complex projects.

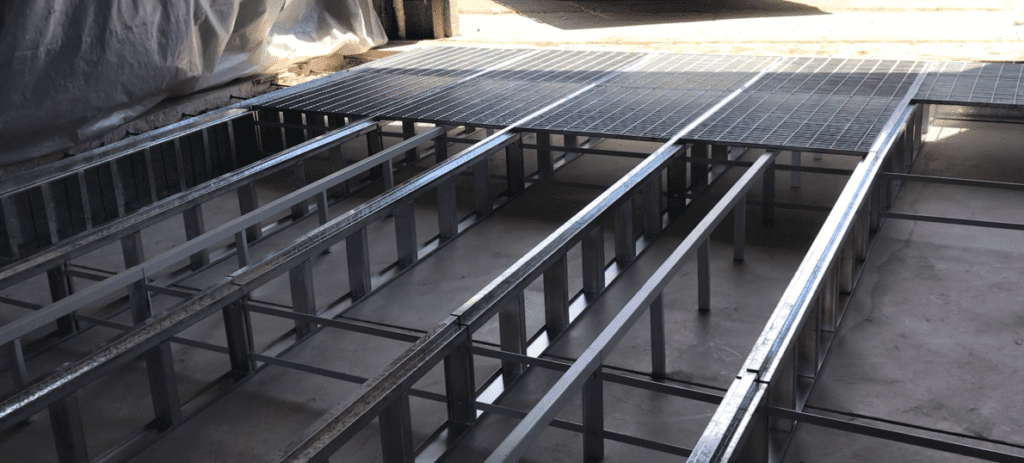

Elevated Downdraft Basement

Elevated Downdraft Basement and Benefits. An elevated downdraft basement offers the advantages of downdraft airflow without the need to dig a concrete pit. This raised metal platform provides fully grated flooring that captures contaminants and dirt below the surface, keeping the workspace spotless. It saves time and installation costs by eliminating concrete work, while still delivering top-tier air circulation and a cleaner painting environment. The Tru Down Air Flow also allows users to adjust airflow as needed, ensuring consistent performance and flexibility. Elevated downdraft basements are designed with sufficient weight and structural capacity to support cars and fleet vehicles, making them a versatile choice for various automotive applications. They also provide adequate space for ventilation, meeting and often exceeding safety and building codes. By avoiding concrete pits deeper than 3 feet, this design simplifies installation and maintenance while maintaining exceptional airflow efficiency and workspace safety.

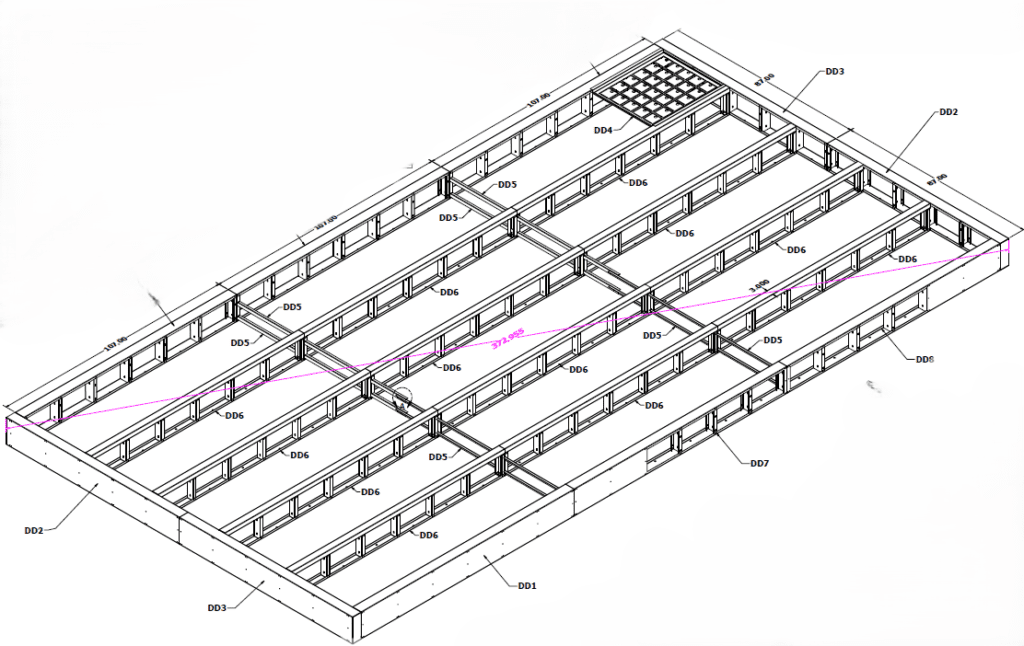

Inground Downdraft Basement

Inground Full Downdraft Basement. An inground full downdraft basement requires a concrete pit installation beneath the spray booth, offering optimal airflow from wall to wall. Fully grated floors and extensive filter systems trap dirt and contaminants below the surface, creating the cleanest possible environment for painting. This setup provides the most powerful and efficient airflow pattern available, drawing air evenly from every point of the booth floor. Though it involves more upfront construction and time, this system delivers unmatched air circulation and exceptional paint job quality. Standard setups can include up to five rows of grates, but the configuration can also be customized depending on your booth size and specific manufacturing needs. This flexibility ensures optimal performance, regardless of the scale or complexity of your projects. By keeping contaminants completely away from the painted surface, it ensures a flawless finish with minimal risk of rework. The inground design also maximizes available booth space, allowing for greater flexibility when working on larger vehicles or complex projects. In the long run, the investment in an inground system pays off through reduced labor costs, improved efficiency, and consistently high-quality results.