Maximize Your Finishing System's Performance with RGI's Quality Parts & Maintenance Solutions

The Importance of Routine Maintenance

Owning and maintaining a finishing system is a significant investment, and ensuring that every component operates optimally is crucial for system longevity and consistent performance. Regular inspections and maintenance are essential to keep your system running smoothly, reduce downtime, and avoid expensive repairs. A well-maintained system also helps ensure compliance with safety regulations while delivering high-quality, consistent finishes.

Why Choose RGI for your Maintenance Needs?

RGI is committed to providing top-quality replacement parts and maintenance solutions for your finishing system. Our full-service parts and filters department ensures quick access to the components you need to keep your equipment in peak condition. With a broad range of parts in stock, we offer fast, reliable shipping across North America to minimize downtime and keep your operations efficient and productive.

Paint Booth Parts & Filters:

We carry a complete selection of filters, including air handling, paint booth, and heater filters. These high-performance filters help maintain airflow and system longevity.

Electrical Components:

We offer essential electrical components such as start/stop components, air proving switches, and manometer/draft gauges, designed for reliable and efficient operation.

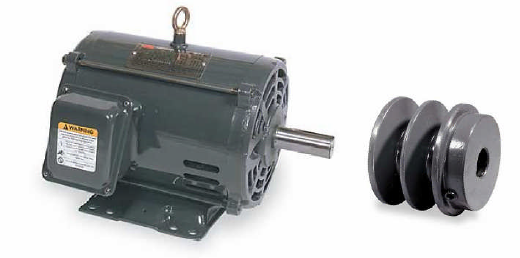

Common Replacement Parts:

RGI provides a variety of replacement parts, including belts, fan blades, control panels, gaskets, door seals, and more, all designed for ease of installation and long-lasting performance.

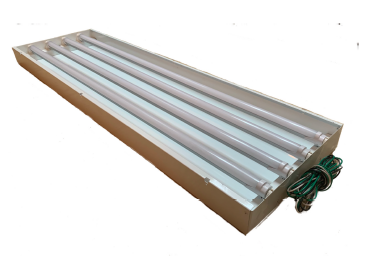

LED Light Fixtures for Paint Booths:

Our LED light fixtures are specially designed for paint booths to ensure optimal lighting and efficiency during operation.

Curtain Walls & Dividers:

Our fire-retardant curtain walls and dividers are perfect for controlling temperature, dust, and contaminants in your workspace, making them ideal for applications like sanding, painting, welding, and woodworking. They meet NFPA 701 regulations.

Door Hardware:

We offer high-quality, weld-free door hardware, including adjustable hinges, latches, and pulls, ensuring a perfect fit and durability.

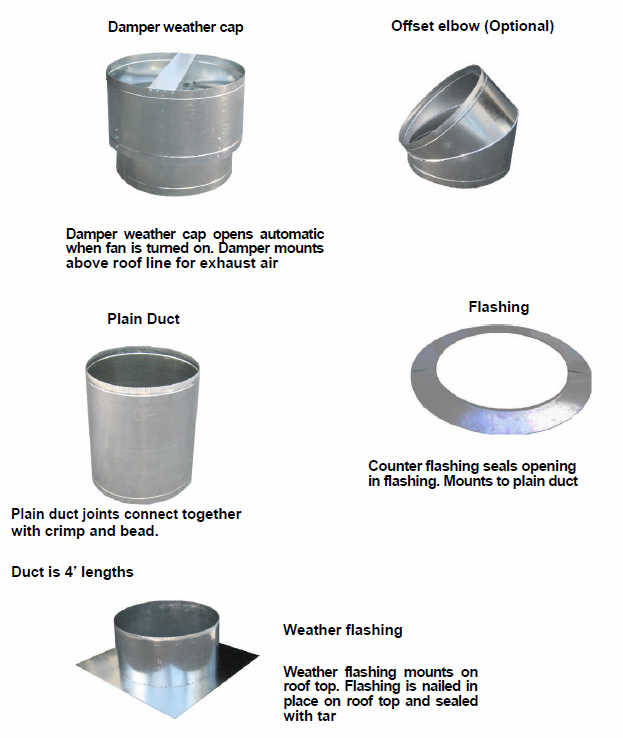

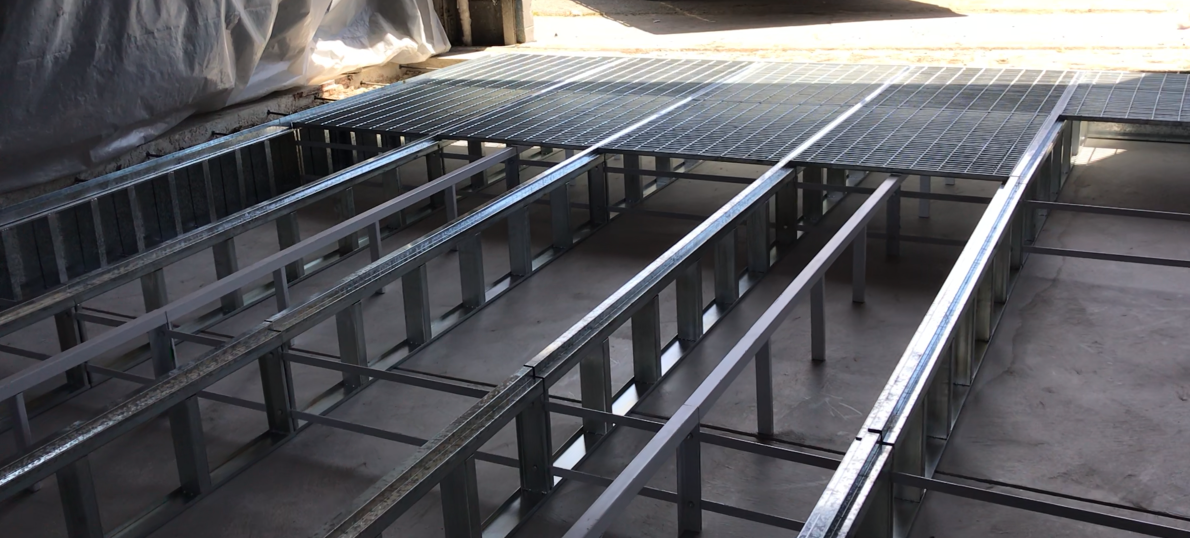

Grating & Duct Options:

For safe access and optimal airflow, we provide steel grating for downdraft booths and a variety of duct options like spiral and connector rings to enhance system performance.

Signs That Maintenance is Needed:

Pay attention to the following signs, which could indicate the need for replacement parts or maintenance:

Damaged light fixtures or electrical components

Unusual noise or excessive heat from motors

Pressure issues due to dirty or clogged filters

Sub-par finishes or disruptions in system performance

Why Regular Maintenance Matters:

Reduce Downtime: Proactive maintenance minimizes the risk of unexpected breakdowns, ensuring uninterrupted operation.

Extend Equipment Lifespan: Routine inspections and repairs help extend the lifespan of your equipment, protecting your investment.

Improve Safety: Regular maintenance reduces the risk of hazards, helping to maintain a safe working environment for your team.

Enhance Quality: A well-maintained finishing system ensures high-quality, consistent results with every use.

Ensure Compliance: Routine maintenance ensures your system complies with safety and environmental standards, preventing costly fines and penalties.